What Are Perforated Sheets and Their Uses in Industrial Applications?

What Are Perforated Sheets and Their Uses in Industrial Applications?

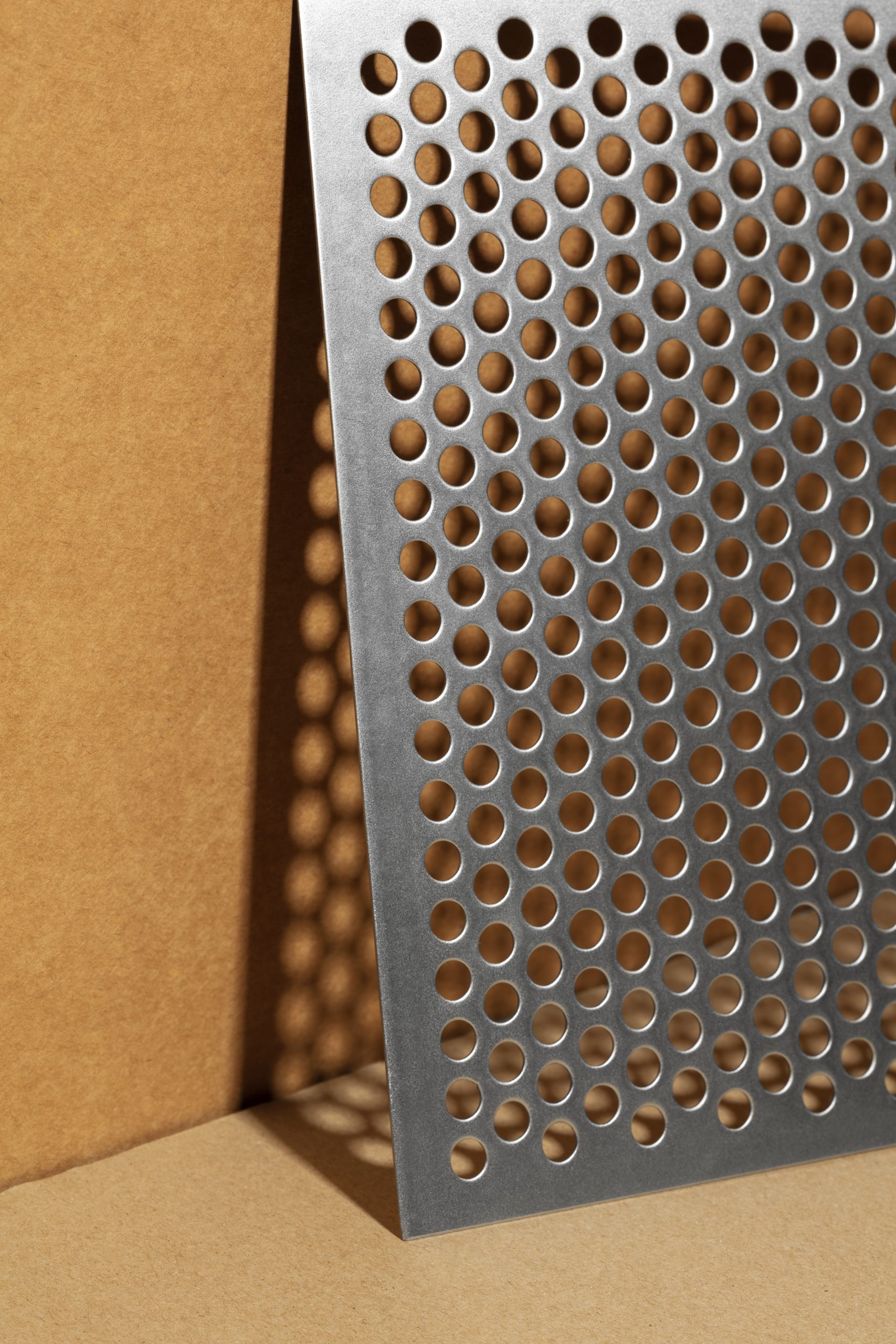

Perforated sheets are versatile metal panels with custom holes, slots, or patterns used across numerous industries. From filtration systems to safety equipment and decorative facades, their applications are both functional and aesthetic — making them a crucial part of industrial fabrication.

At Jack’s Engineering Works, we fabricate high-quality perforated sheets tailored to client specifications in steel, aluminium, brass, and other alloys.

1. Common Industrial Uses of Perforated Sheets

- Filtration systems – air, water, oil filters

- Acoustic panels – noise control in machines

- Ventilation grilles – airflow management

- Safety guards & screens – machinery protection

- Architectural designs – walls, facades, ceilings

2. Benefits of Using Perforated Metal Sheets

Perforated sheets offer strength without weight, improved airflow, aesthetic flexibility, and cost-effective customization.

3. Types of Patterns Available

We offer round hole, square hole, hexagonal, slotted, and decorative patterns. All sheets are machine-punched to precision tolerances for uniformity.

4. Materials & Finishes

Choose from stainless steel, galvanised steel, aluminium, copper, or brass. Available in plain, powder-coated, or brushed finishes depending on your application.

5. Why Choose Jack’s Engineering Works?

We deliver industry-grade perforated sheets that meet ISO standards and are backed by expert engineering, on-time delivery, and optional installation support.

Perforated Sheets | Sheet Metal Fabrication | Powder Coating | Custom Pipe Work