What Are the Advantages of MIG, TIG, Oxy, Stick, and Spot Welding?

What Are the Advantages of MIG, TIG, Oxy, Stick, and Spot Welding?

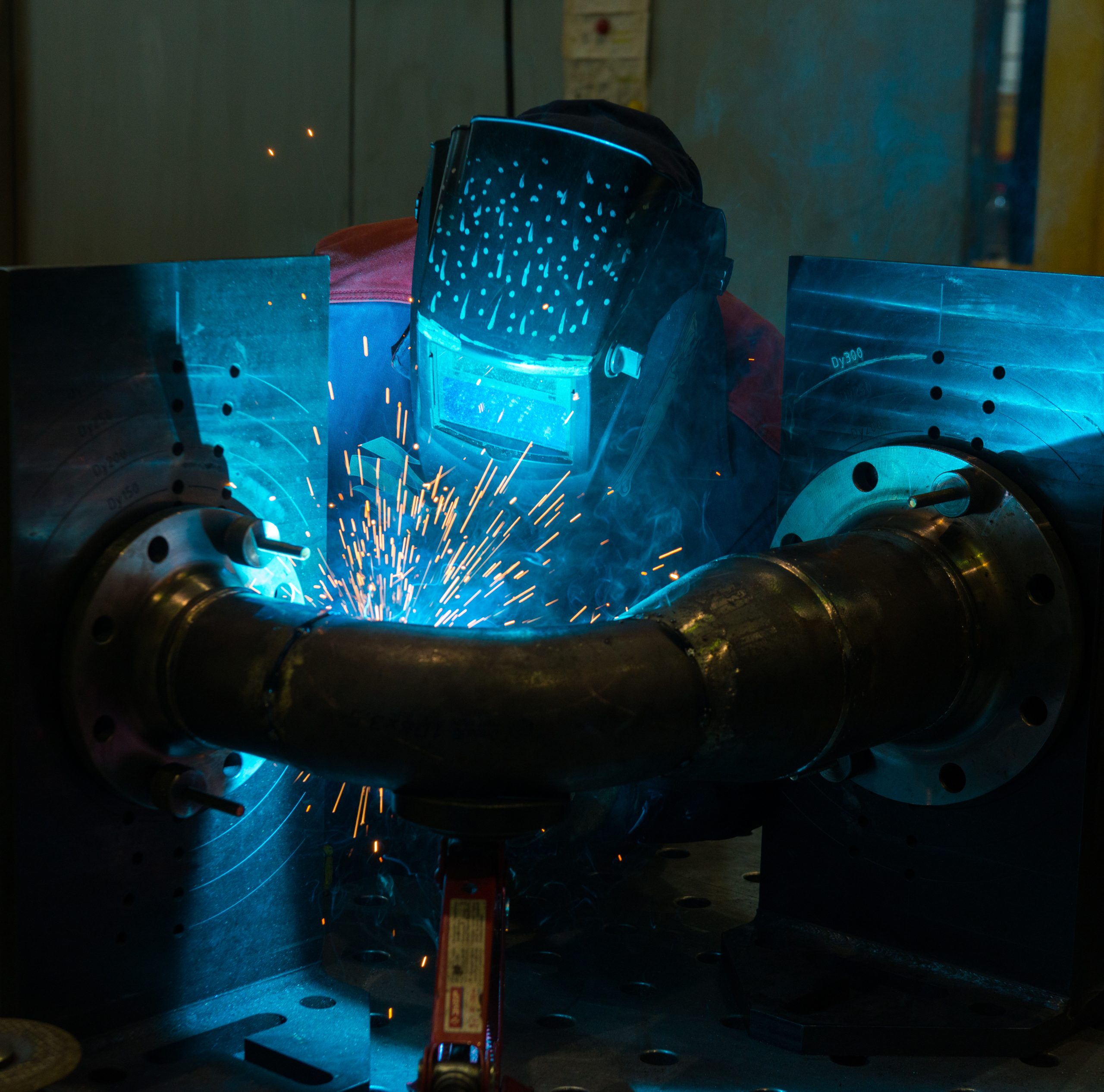

Welding is the foundation of countless industrial and commercial applications. From car manufacturing and construction to delicate metalwork and repair jobs — the right welding method ensures strength, durability, and precision. This guide explores the five most popular welding methods:

MIG, TIG, Oxy-Acetylene, Stic, Spot Welding ,

Understanding the unique strengths of each method allows businesses and individuals to select the most suitable welding technique for their specific needs. Whether you're looking for metal fabrication, industrial welding, or custom welding, choosing the right method makes all the difference. Trust professional welding services to get the job done with precision.

1. MIG Welding (Metal Inert Gas)

MIG welding is widely used due to its speed and ease of use. It involves feeding a wire electrode through a welding gun and shielding the arc with gas. This method is best suited for thick materials like structural steel, vehicle frames, and machinery parts.

- Highly efficient for production environments

- Great for beginners due to easier control

- Minimal cleanup and high weld quality

2. TIG Welding (Tungsten Inert Gas)

TIG welding provides precise, clean welds, ideal for thinner materials and decorative or critical applications. It uses a non-consumable tungsten electrode and requires more skill, but the results are outstanding.

- Superior control over weld quality

- Perfect for stainless steel and aluminum

- Common in aerospace and fine art welding

3. Oxy-Acetylene Welding (Gas Welding)

Oxy welding is a classic method using a flame to melt and join metal. It’s versatile and suitable for both welding and cutting. While less common in industrial fabrication today, it’s still widely used for repair work and plumbing.

- Useful for metal cutting and heating

- No electricity required

- Affordable and portable setup

4. Stick Welding (Shielded Metal Arc Welding)

Stick welding is robust and portable, perfect for outdoor projects and structural welding where conditions aren’t controlled. It's often used for heavy construction, shipbuilding, and pipeline work.

- Works in windy or dirty conditions

- Lower equipment cost

- Ideal for thick, rough surfaces

5. Spot Welding

Spot welding is commonly used for joining thin sheet metal — especially in the automotive and appliance industries. It uses pressure and electric current at specific “spots” to create strong welds.

- Fast and automated

- Clean finish, no filler required

- Best for large-volume assembly

Each welding type has a unique set of advantages, making them suitable for specific industries and jobs. Whether you’re looking for heavy-duty fabrication, intricate detailing, or quick repairs — choosing the right welding method makes all the difference.

Get a Welding Quote